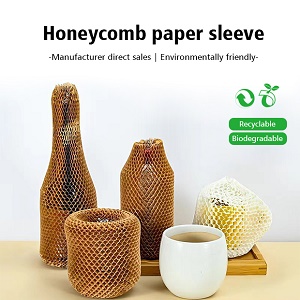

Honeycomb paper sleeves are increasingly gaining popularity as a sustainable and versatile packaging solution. These innovative packaging materials are made from layers of paper bonded together to form a honeycomb structure. They are known for their strength, durability, and eco-friendly properties. So, where are the application scenarios for honeycomb sleeves?

One of the primary applications of honeycomb paper sleeves is in the shipping industry. Many companies are now opting for sustainable packaging materials to reduce their carbon footprint. Honeycomb paper sleeves provide excellent protection for fragile items during transportation. They can withstand high levels of compression and impact, ensuring that the products arrive safely at their destination. Moreover, the honeycomb structure also acts as an insulator, keeping the products secure from temperature fluctuations. This makes honeycomb sleeves ideal for shipping delicate and perishable goods such as electronic devices, glassware, and food items.

Another application scenario for honeycomb sleeves is in the furniture industry. Furniture pieces are often prone to scratches and damages during transit or storage. Honeycomb paper sleeves offer a cushioning effect and shock absorption properties, ensuring that the furniture remains in pristine condition. The sleeves can be easily customized to fit furniture of various shapes and sizes, providing a snug and secure fit. Whether it’s for transporting furniture to retail stores or protecting items during house moves, honeycomb sleeves offer a cost-effective and sustainable packaging solution.

In the e-commerce sector, honeycomb paper sleeves are becoming increasingly popular for packaging smaller items such as cosmetics, electronic accessories, and small appliances. These sleeves can be easily folded and assembled, making them convenient for packing various types of products. Additionally, they can be customized with brand logos and designs, providing an opportunity for companies to enhance their branding and customer experience. As consumers become more environmentally conscious, using honeycomb paper sleeves for packaging can help businesses attract and retain customers who prioritize sustainability.

Honeycomb sleeves also find applications in the automotive industry. During the manufacturing and transportation of automobiles, certain components need to be protected from damage. Honeycomb paper sleeves can be tailored to fit specific parts, providing cushioning and protection against scratches and impacts. They are also lightweight, reducing the overall weight of the packaging and minimizing shipping costs. Additionally, honeycomb sleeves are recyclable, aligning with the industry’s efforts to reduce waste and promote sustainability.

Beyond these industries, honeycomb paper sleeves have a wide range of potential applications. They can be used in the construction sector for packaging and protecting building materials or in the medical field for sterilized packaging of medical devices. Moreover, honeycomb sleeves can also be utilized in the arts and crafts industry for product displays and packaging of handmade products.

In conclusion, honeycomb paper sleeves offer a sustainable and versatile packaging solution for various industries. From shipping and furniture to e-commerce and automotive, the applications of honeycomb sleeves are extensive. Moreover, their eco-friendly properties make them a preferred choice for businesses and consumers who prioritize sustainability. As the demand for sustainable packaging continues to grow, honeycomb sleeves are expected to play a significant role in meeting these needs in a cost-effective and environmentally friendly manner.

Post time: Aug-24-2023